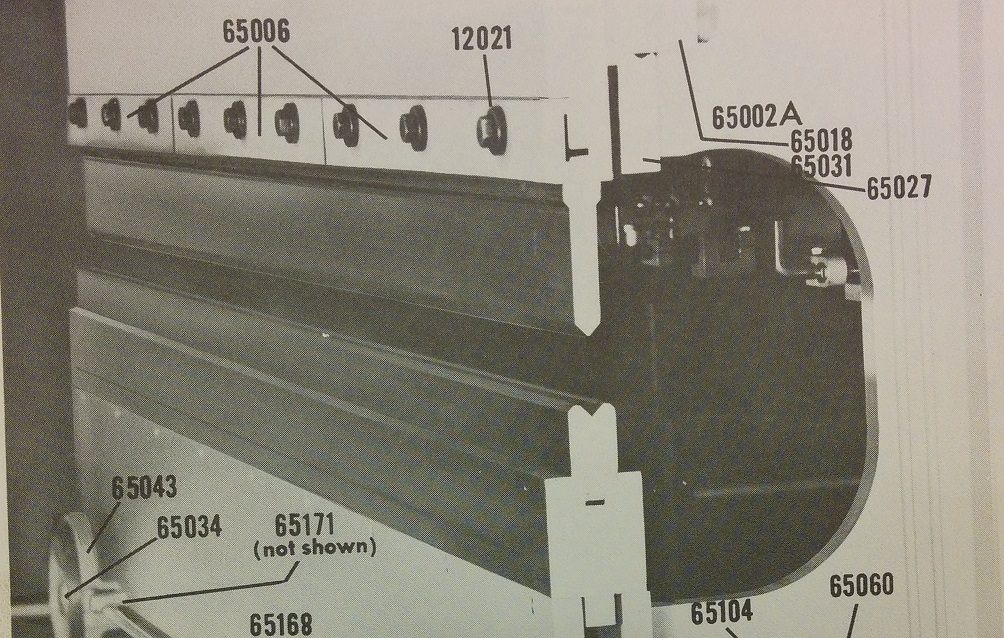

Additional processing is also available as a service. Mechanical sheet metal forming, punching, and shearing add flexibility to better suit your design needs – especially when working in 3D. We are equipped with a variety of machines which can perform several operations including, but not limited to, bending, punching, shearing, grinding, and polishing.